Tests protective materials for resistance to high-temperature contact heat by measuring the time for

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

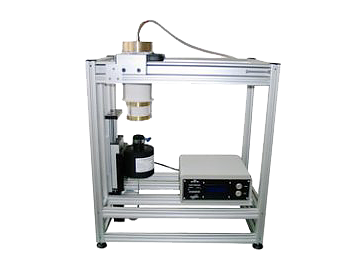

The contact heat resistance tester evaluates materials' ability to withstand high-temperature contact heat by measuring the time required for specimen temperature to rise 10°C under specified pressure and heating conditions. This critical time determination provides quantitative assessment for thermal protection material development and performance evaluation.

Suitable for testing thermal protection performance of firefighter suits, heat-resistant gloves, and related materials.

EN 702:1994 Protective clothing - Protection against heat and flame - Test method: Determination of the contact heat transmission through protective clothing or its materials

EN 12477:2001+A1:2005 Protective gloves for welders

EN 407:2020 Protective gloves and other hand protective equipment against thermal risks (Heat and/or fire)

ISO 12127-1:2015 Clothing for protection against heat and flame - Determination of contact heat transmission through protective clothing or constituent materials - Part 1: Contact heat produced by heating cylinder

BS EN 22313:2015 Protective clothing - Protection against heat and flame - Determination of contact heat transmission through protective clothing or its materials

1. Wide Temperature Range Heating Capacity: The built-in 25.2mm heating element, combined with a temperature sensor and setting device, allows for precise temperature control within the 100℃-500℃ range, covering the testing needs of most thermal protection materials.

2. Precise Thermal Insulation Design: The heating element is encased in insulation material and employs a double insulation structure, effectively preventing heat loss, reducing environmental interference with test results, and ensuring data accuracy.

3. Standard Pressure Supply: A counterweight is positioned above the heating element, providing a stable 49N contact pressure, meeting the test pressure requirements of standards such as EN 702 and ISO 12127.

4. High-Precision Temperature Measurement: Equipped with an anodized aluminum temperature measuring plate (25mm size), the temperature measurement accuracy reaches ±0.1℃, accurately capturing sample temperature changes.

5. High Testing Efficiency: It can quickly and accurately measure the high-temperature contact thermal critical time of materials, aiding in the research and performance evaluation of thermal protection materials.

6. Multi-standard compatibility: Complies with multiple international/European standards such as EN 702. EN 12477. EN 407. and ISO 12127. and can be used for thermal protection performance testing of various materials such as thermal insulation clothing and protective gloves.

| Parameter | Specification |

|---|---|

| High-temperature heating element | Φ25.2mm; equipped with sensitive thermocouple sensor; temperature settable from room temperature to 500°C |

| Insulated heating element coating | Prevents heat dissipation interference |

| Contact force | 49N (provided by weighted pressure plate) |

| Temperature probe | Alumina-anodized (Φ25mm, 5mm); ±0.1°C accuracy |

| Motorized sample holder system | 5mm/s precise motion control; contacts heating body at controlled speed |

| One-touch testing & LED display functions | Displays initial specimen temperature, real-time temperature, critical 10°C rise time (±0.1s resolution) |

| Dimensions (W×D×H) | 800×50×550mm |

| Power requirement | 230V 50Hz AC |

25.2mm built-in heating element (including temperature sensor and temperature setting device); Heating element equipped with double thermal insulation material; 49N counterweight; Aluminum anodized temperature measuring plate (25mm size, temperature measurement accuracy ±0.1℃); Thermal resistance (thermometer) (dedicated to sample heating test, movement speed 5mm/s); Instrument main body fixing frame and sample clamping assembly.

1. Sample Preparation and Pretreatment

According to the corresponding test standards (e.g., EN 407. ISO 12127), cut the samples: for thermal insulation clothing materials, take standard-sized samples; for protective gloves, select samples from key protective areas such as the palms/knuckles.

Place the samples in a standard atmospheric environment (temperature 21±1℃, relative humidity 65±2%) for at least 8 hours to acclimate and ensure sample stability.

2. Instrument Inspection and Preparation

Inspect instrument components: confirm that the 25.2mm heating element, aluminum temperature measuring plate (25mm), temperature sensor, 49N counterweight, etc., are intact.

Connect the power supply, start the instrument, and preheat the system to standby mode. Confirm that the insulation material of the heating element is undamaged to avoid heat loss affecting test accuracy.

3. Test Parameter Settings

Select the corresponding test standard (e.g., EN 702/ISO 12127) and set the following on the instrument's operating interface:

Target temperature of the heating element (can be selected within the range of 100℃-500℃, according to standard requirements, such as 200℃/300℃);

Temperature monitoring threshold (usually set to "temperature rise of the measuring plate by 10℃", matching the test requirements of the Heat Transfer Index (HTI);

Confirm the counterweight pressure is 49N (the pressure value corresponding to the standard counterweight of the instrument).

4. Sample Clamping

After the heating element temperature stabilizes to the target value, lay the sample flat between the heating element and the aluminum measuring plate, ensuring the sample is fully in contact with both without wrinkles;

Install the 49N counterweight to bring the sample into contact with the heating element under the specified pressure.

5. Test Initiation and Data Recording

Start the test program; the instrument automatically monitors the temperature change of the temperature measuring plate.

When the temperature of the temperature measuring plate rises to the set threshold (e.g., a 10°C increase), the instrument automatically records the time taken (i.e., the Heat Transfer Index, HTI).

6. Parallel Testing and Result Processing

Repeat the above steps for 3-5 parallel samples of the same specimen, as required by the standard, to complete multiple sets of tests. Calculate the average HTI of all parallel samples, and evaluate the high-temperature contact heat resistance of the specimen based on the corresponding standard (e.g., ISO 12127) classification.

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com