The burning manikin system is used to test the overall thermal protection performance of protective

WhatsApp : +86 13816217984

Email : info@qinsun-lab.com

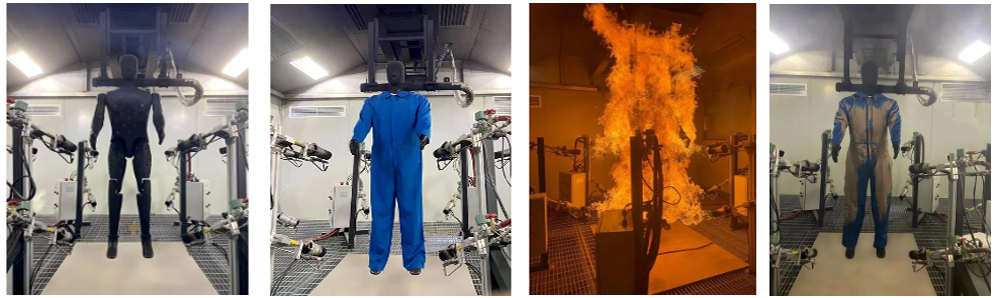

The burning manikin system is used to test the overall thermal protection performance of protective clothing.Complete combustion manikin system, which consists of combustion chamber, burning manikin and gas control system and other components.

The Burning Manikin System is primarily applied in the following areas:

Fire Environment Simulation: This system simulates high-risk fire environments, realistically recreating flashover scenarios. Using a burning manikin testing system and accompanying software, it evaluates the flame-retardant performance of protective clothing.

Thermal Protection Performance Assessment: By placing thermal sensors on the manikin model, it measures and calculates the heat and temperature transmitted through the clothing to various parts of the manikin's surface, thereby predicting the possible locations and extent of burns.

Fire Environment Research: This system helps researchers analyze the heat transfer mechanism between the heat source, clothing, and the human body in a fire environment, improving the thermal protection performance of protective clothing.

Firefighter Protection: Through burning manikin testing, it evaluates the heat insulation performance of fire suits, optimizing designs to reduce the rate of burns.

These applications contribute to improving the survivability of firefighters and soldiers under high-intensity flame conditions.

EN ISO 11612:rotective clothing - Clothing to protect against heat and flame - Minimum performance requirements

EN ISO 11611:Protective clothing for use in welding and allied processes - Minimum basic safety requirements

ISO 13506:Protective clothing against heat and flame - Test method for complete garments - Prediction of burn injury using an instrumented manikin

EN469:2005:Protective clothing for firefighters - Performance requirements for protective clothing for firefighting

ISO13506-1:Protective clothing against heat and flame- part1: Test method for complete garments-Measurement of transferred energy using an instrumented manikin

ISO13506-2:Protective clothing against heat and flame- part2: Skin burn injury prediction- Calculation requirements and test cases

ASTM F1930:Standard test method for evaluation of flame-resistant clothing for protection against fire simulations using an instrumented manikin

GB8965.1:Protective clothing - Flame retardant protective clothing

The burning manikin system is composed of:

1. computer combustion dummy;

2. thermal sensor group;

3. flame generator;

4. computer control module;

5. data acquisition and processing module;

6. burn analysis module.

High-precision measurement: Utilizing 124 thermal sensors, it accurately measures changes in human skin temperature to predict burn severity.

Repeatability: Test results can be repeated in simulated fire environments, ensuring accuracy and reliability.

Rapid testing: The system can complete tests quickly, suitable for rapid assessment and quality control.

Versatility: Applicable to various types of protective clothing, such as flame-retardant suits and fire-fighting suits, providing comprehensive thermal protection performance evaluation.

Standardized testing: Complies with international standards such as ISO 13506 and ASTM F1930. ensuring international recognition of test results.

These features make the burning mannequin system of significant value in the field of safety protection, effectively improving the thermal protection performance of protective clothing and ensuring personnel safety.

| Parameter | Description |

| Dimensions (L×W×H) | 14m × 6m × ≥6m |

| Weight | 2000 kg |

| Thermal Sensors | Monitor heat flux changes on mannequin surface; quantity varies by design |

| Combustion Flame Array | Multiple propane generators arranged around mannequin to simulate fire |

| Gas Supply System | Provides stable gas via high-pressure tanks and pipelines |

| Combustion Chamber | Houses flame array and mannequin for safe, controlled experiments |

| Data Acquisition System | Collects data from thermal sensors with processing units and cables |

| Testing Software | Controls experiments, analyzes data, and generates visual reports |

| Calibration Tools | Ensure accuracy and reliability of sensor data through calibration |

1. The burning manikin model uses 1: 1 adult male model, the material is FRP with stable, flame inert and high strength performance, and 2 ~ 3mm thickness, 1.72m2 surface area. There are a certain number of sensors in the manikin model’s head, trunk, legs and arm surface evenly. The manikin model’s outer surface paints black and flame retardant coating. The processed sensor data export lines on the head facilitate the instrument to capture the data signal.

2. The sensor group includes thermal sensor and pressure sensor. The heat sensor consists of more than 120 heat flow sensors, which are evenly distributed on the manikin's surface, and each sensor represents the physical condition of the skin of a certain surface area. Numbered every sensor, and if the temperature value calculated by the sensor passes burns are estimated to meet the two or three burning degrees, then mark them into a simulated digital human body model with different colors. Since the flame temperature change is a dynamic process, the test sensor temperature range is higher and the response time is shorter to achieve the flame dynamic process of the test. Pressure sensor is mainly used to measure the gas container and gas pipeline gas pressure value, to ensure safe and controllable experimental.

3. The flame generation device consists of 6 groups of 12 propane flame generators around manikin. Each group of flame generators consists of a high pressure liquefied gas tank, a buffer gas tank, a pressure pipe and a gas pressure sensor, a adjustable flame nozzle, and a pilot flame device. Flame action time is controlled by the computer control simulation module, the flame intensity during this period maintains uniform and stable.

4. The computer control module is composed of pre-programmed software. The main function is to automatically check the status of each group of sensors associated with the experiment before the start of the experiment. Send the command when no problem. In the course of the experiment, the computer control program controls the time and intensity of the flame generator, automatically guide the data processing module and record the data changes of the various sensors. In the end of experimental stage, downloaded and saved the recorded data into the form of the document, and guide the exhaust ventilation system on the combustion test chamber for ventilation.

5. Data acquisition and processing simulation. With the help of computer control module, preprocess the signal of the amplification, conversion and storage data for control temperature sensor and heat flow sensor acquisition. the heat flow signal transfer into the corresponding temperature value through the model, and then the results are temporarily stored for the burn estimator module use.

6. The burn estimation module is intended to estimate the extent of burns caused by the flame. The information of the manikin surface temperature value obtained by the sensor is input to the burn estimation model. After the burn estimation operation, the burn integral value and the burn program value are obtained. Combined with the plot of the digital human body model to get the second and third degree burns on the scattergram manikin's surface.

The steps for operating the burn mannequin system are as follows:

Prepare the dummy: Dress the dummy in the complete protective suit to be tested and adjust its posture.

Calibrate the combustion system: Ensure the heat flux meets the standard requirements.

Ignition and exposure: Remotely ignite all nozzles simultaneously, instantly engulfing the dummy in flames for a preset time.

Extinguishing and cooling: Automatically shut off the gas after the preset time and may activate the water spray system to cool the dummy.

Data download and analysis: Download sensor data and generate a burn assessment report through software analysis.

Quantitative assessment: Provide objective, quantitative data, not just a binary result of "whether it has burned through."

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com